ATOPAD

Tolerance Analysis by Adaptive Polyhedra

| The AToPAd project is an original research program in tolerance modeling and simulation. This project aims at the representation complex phenomena through an approach that adaptively integrates data from geometric and mechanical models according to the functional requirements to be met. The objectives can be differentiated in two levels: |

- At the part level, to integrate representative geometric details of the production processes,

- At the mechanism level, to integrate a contact architecture coupled with a behavior representative of the functioning of a mechanical system.

At the part level

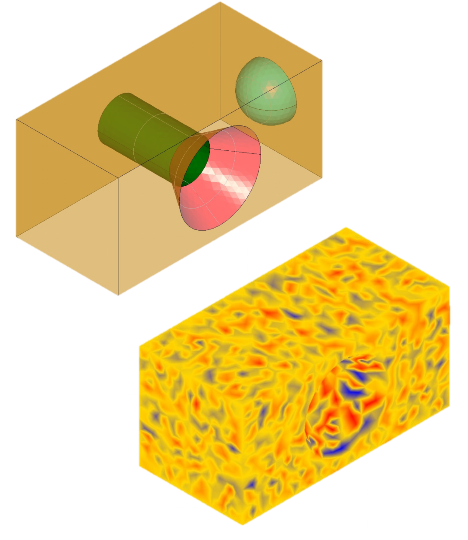

Skin Model

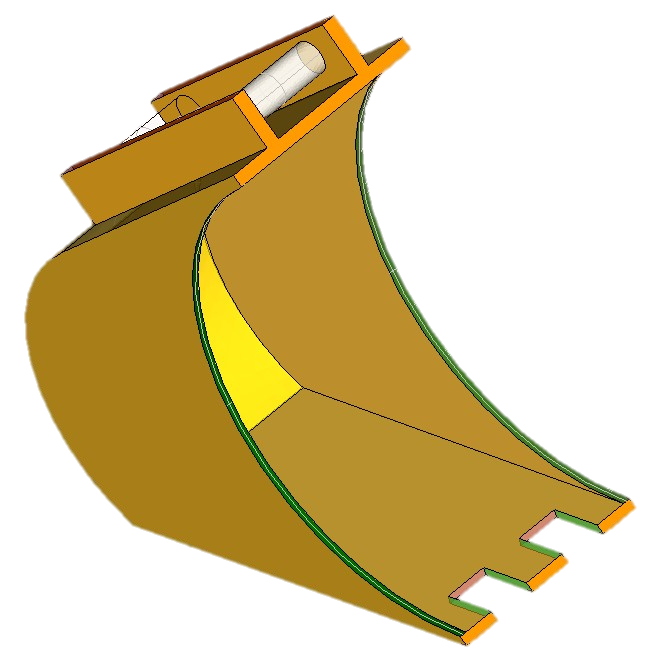

The Skin model is a theoretical surface model of non-ideal geometry. It encompasses all the possible defects of a workpiece. The ISO TC 213 adopted Ballu and Mathieu’s work [1], and the skin model of a workpiece is defined in the ISO standard [2] as: “model of the physical interface of the workpiece with its environment”

Skin Model Shape

A Skin Model Shape can be understood as a finite virtual Skin model representative. It represents one instance of defaults of a workpiece.

Deviation modeling

The deviation modeling is carried out distinctively according to the data available at a given moment in the product design process; when data from measurements or simulations is available then we consider to be in the observation stage; when these data is not available, we are in the prediction stage.

At the prediction stage we can make a first classification of the approaches by type of deviations they model: systematic or random deviations. The following methods are implemented in the project.

Systematic | Random |

|---|---|

|

|

The deviation modeling process is carried out using methods mentioned above, they are integrated in new release of PolitoCAT that can be downloaded below.

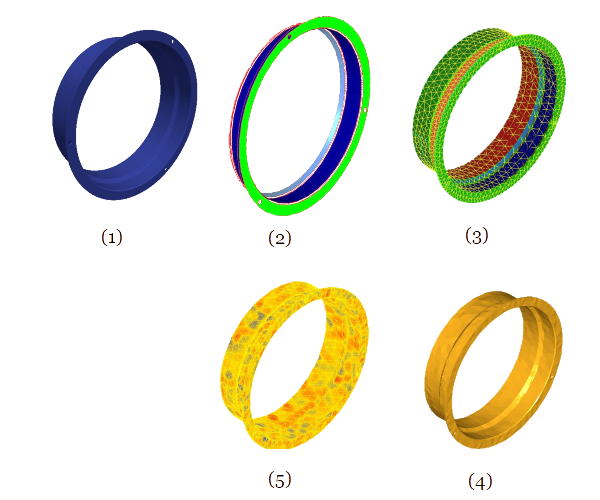

The process is as follows:

1. 3-D modeling of the part

2. Partioning of part in tolerance features

3. Discretization: meshing, tessellation

4. Deviation modeling: observation, prediction

5. Visualization

At the mechanism level

Contact modeling

The first part of the research on contact modeling is done with a rigid contact model. The contacts can be between ideal or non-ideal surfaces.

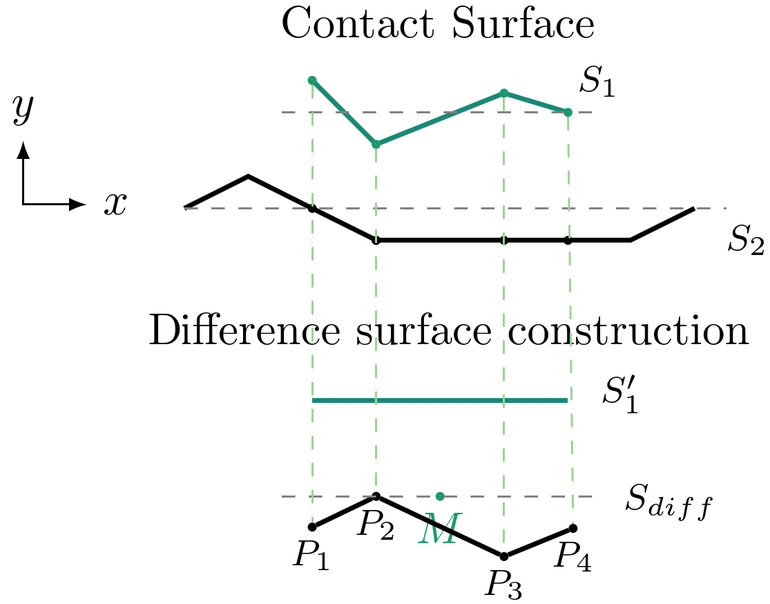

Difference surface method

This method consists in calculating an equivalent surface that embodies the deviations of two features in contact transforming the contact of two features with form defects into the contact of an equivalent feature and a feature with no deviations.

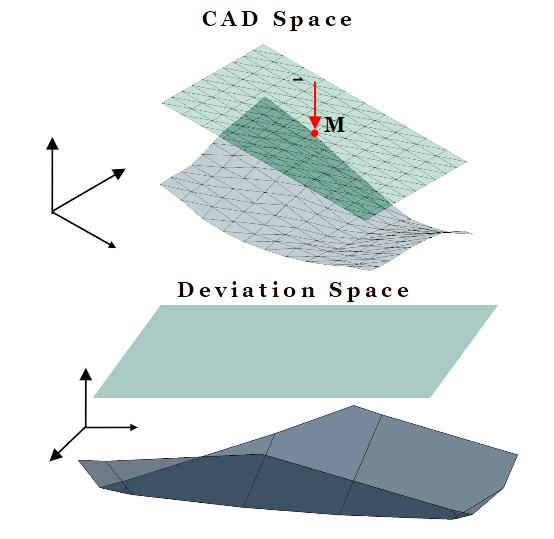

Matting forces as half-spaces

A method that exploits the advantages of the deviation space and duality properties of the screw theory was implemented. It allows to determine the contact between matting features with form defects in rigid-body models.

The load boundary conditions are represented as a additional half-spaces in the deviation domain introducing new restrictions in the form of half-spaces.

A single polyhedron operand carries now the information about:

- The physical restrictions that come from the geometry

- The degrees of freedom of the contact

- The restrictions coming from the loading conditions.

Bibliography

[1] Mathieu, L., & Ballu, A. (2007). A model for a coherent and complete tolerancing process. Models for Computer Aided Tolerancing in Design and Manufacturing - Selected Conference Papers from the 9th CIRP International Seminar on Computer-Aided Tolerancing, CAT 2005, 35–44. https://doi.org/10.1007/1-4020-5438-6_5

[2] ISO-17450-1. (2011). BSI Standards Publication Geometrical product specifications (GPS) — General concepts Part 1 : Model for geometrical specification. In ISO.

Research

Conferences

An integrated open source CAT based on Skin Model Shapes

Carlos Andres Restrepo Garcia,Denis Teissandier, Nabil Anwer, Vincent Delos, Yann Ledoux, Laurent Pierre

17th CIRP Conference on Computer Aided Tolerancing, Jun 2022, Metz, France

Software and data

The algorithms developed in the frame of the project are included in the latest version of PolitoCAT. PolitoCAT is a free software under the GNU LGPL license, with a kernel based on politopix and a graphical interface

Download PolitoCAT v2.0.2 for Windows | |

Download tutorial PolitoCAT v2.0.2 written by C. Restrepo & al. | |

Download Presentation CIRP CAT - Juin 2022, Metz, France |

Members

| Carlos Restrepo (I2M-LURPA) PhD student in the frame of AToPAd project at University of Bordeaux. Contact:carlos.restrepo@u-bordeaux.fr |

Denis Teissandier (I2M) Professor University of Bordeaux - Manager of the master's degree in mechanics. Contact:denis.teissandier@u-bordeaux.fr | |

Nabil Anwer (LURPA) Professor, Paris Saclay University - Deputy Director, Automated Production Research Laboratory (ENS Paris-Saclay) - Director, PLM Innovation Center, Tsinghua University Contact:nabil.anwer@ens-paris-saclay.fr | |

Vincent Delos (I2M) CNRS Engineer – I2M, University of Bordeaux Contact:vincent.delos@u-bordeaux.fr | |

Yann Ledoux (I2M) Associate professor at University of Bordeaux Contact: yann.ledoux@u-bordeaux.fr | |

Laurent Pierre (LURPA) Associate professor at École normale supérieure Paris-Saclay – University Paris-Saclay Contact: laurent.pierre@ens-paris-saclay.fr |

Laboratories

Institut de Mécanique et d'Ingénierie Bordeaux

I2M - UMR 5295 CNRS

Esplanade des Arts et Métiers

33405 Talence Cedex - France

Laboratoire Universitaire de Recherche en Production Automatisée

LURPA, ENS Paris-Saclay

4 avenue des Sciences

91190 Gif-sur-Yvette - France